LOCTITE®

LOCTITE® EA 3478 TM

| Technology Epoxy |

| Chemical Type Epoxy |

| Appearance – Part A Metallic gray Appearance – Part B White Appearance (Mixed) Gray |

| Components Two part – Resin & Hardener |

| Mix Ratio, by weight – Resin : Hardener 4 : 1 |

| Mix Ratio, by volume – Resin : Hardener 7.25 : 1 |

| Cure Room temperature cure after mixing |

| Application North America – Surface Repair |

| Application Temperature 15 to 30°C (59 to 86°F) |

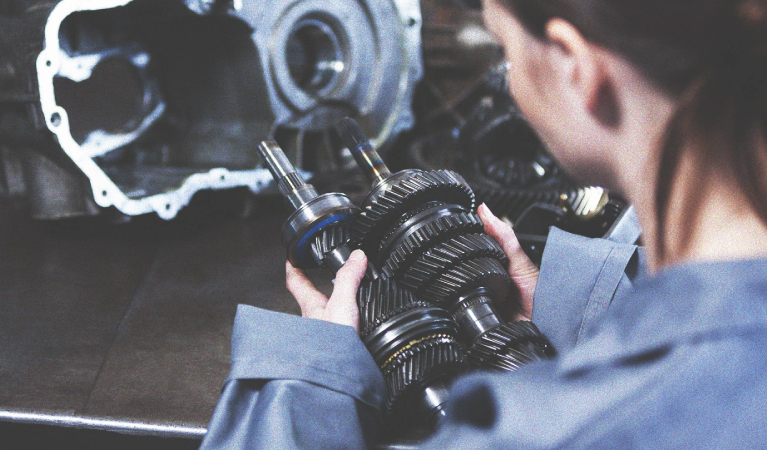

| Specific Benefit ●Resurfaces and repairs worn or corroded metal parts● Excellent machinability● Ferro-silicon filled system -cures to metal-like finish● Rebuilds worn parts fast – limits downtime● Resists corrosion, abrasion, and chemicals |

LOCTITE® EA 3478™ is a two-part ferro-silicon filled, 100% solid epoxy resin system. It is ideal for restoring parts worn by mechanical impact and/or corrosion. Typical applications are restoring tolerances to worn shafts, repairing worn keyways, repairing damaged housings, filling pitted surfaces in worn machinery, and restoring fit to bearing housings.